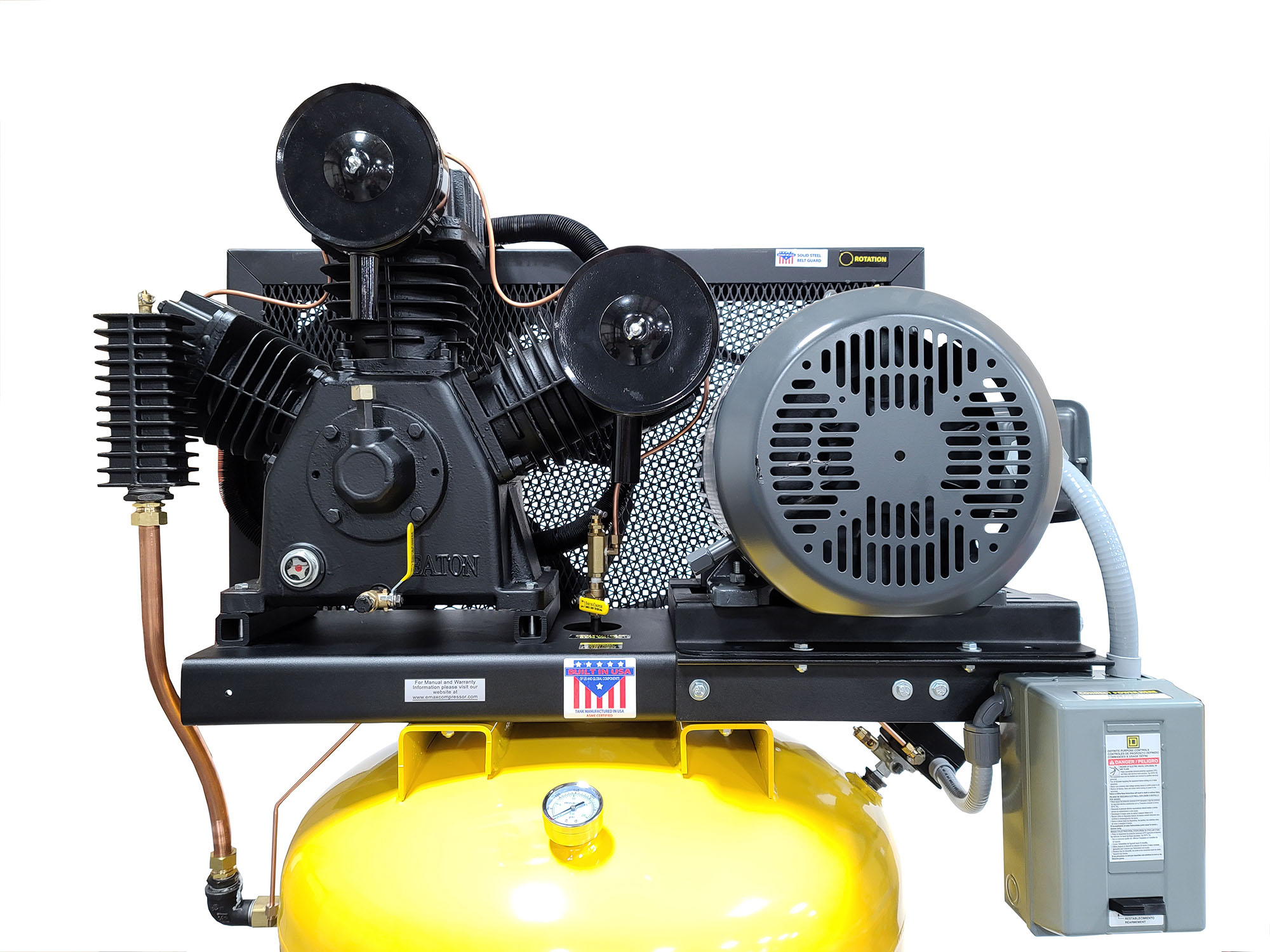

Standard voltages for homes (110V) will only operate compressors up to three horsepower. The voltage will determine the horsepower capacity available without expensive modifications. Separate cast cylinders in 2-stage compressors – for better cooling.Oil monitoring device – prevents low oil damage.One-piece connecting rods – eliminates the need for adjustments.Stainless steel finger valves – eliminates corrosion.Splash lubrication – provides reliable design.Minimal moving parts – reduces maintenance.Cast-iron construction – for durability.A small tank means the compressor has to work harder to keep up with demand. A big tank means there is more pressurized air available for output. Air TankĪir tanks help eliminate pulsation in the airline and provide storage when demand for air exceeds the capacity of the compressor. Let your cfm and psi requirements determine horsepower for you, don’t just buy the highest horsepower compressor. The higher the horsepower, the more air (cfm) the compressor can produce.

Cfm is stated in two different forms – piston displacement (pd) or actual cubic feet per minute (acfm). Air FlowĬonsidering the cubic feet per minute (cfm) reflects the amount of usable air available for work is essential. Check the manufacturer’s details for all your equipment. Make sure the pounds per square inch (psi) of your industrial air compressor matches or exceeds the psi requirement of your neediest air tools and pneumatic equipment. Ensure these are all taken into account when setting up the machine. Will you use it every day or occasionally? Will your demands for compressed air be relatively constant in a day, or will they vary? Outdoor or IndoorĪn outdoor industrial air compressor will need protection from the elements, and an indoor one will require ventilation. Here are a few things to look for when selecting an industrial air compressor: Type of WorkĪn important factor in determining the right industrial air compressor will depend on the type of work you will be doing. The type that is right for your business will depend on how you plan to use it, what tools you will use it with, and your available resources. You want to choose a compressor that will give you the correct capacity and operating pressure with the features vital to getting your job done. The two main things to consider are size and features. And, there are many things to take into account.

There is a wide range of options offering various motor types, sizes and designs, and features. Before you go out shopping and choosing an industrial air compressor, it’s essential to examine your needs first because it’s not as simple as you may think.

0 kommentar(er)

0 kommentar(er)